UL 268 is the standard that governs the operation of smoke detectors used within the United States, and the new 7th Edition of UL 268 addresses two significant issues: mattresses and hamburgers. And the Bosch FCP-350 smoke detector series meets these high standards.

Let's first start discussing the impact of new mattress manufacturing materials. Polyurethane foam has gained popularity as a material for mattresses in recent times. These mattresses are more affordable, offer better support, and are easier to ship compared to traditional mattresses. However, polyurethane foam is highly flammable and burns rapidly and intensely. Unfortunately, the current generation of smoke detectors struggle to detect a burning foam mattress in time to alert occupants to evacuate.

Secondly, many people have experienced nuisance alarms triggered by cooking food. Burning your dinner significantly increases the chances of setting off your smoke detectors. The story of the boy who cried wolf teaches us the dangers of repeated false alarms. In the event of a real emergency, people may react slower and treat the alarm with less urgency.

To address these issues, UL developed the broiling hamburger test, officially known as the "cooking nuisance hamburger and flaming PU test." This test determines if an average smoke detector can differentiate between the smoke produced by normal cooking conditions and the smoke that may indicate an early-stage, potentially dangerous fire. At the time, almost every smoke detector on the market failed this test.

The 7th Edition of UL 268 mandates that smoke detectors pass both of these tests.

Smoke detectors must be capable of quickly and accurately detecting a burning foam mattress while disregarding smoke generated by normal cooking.

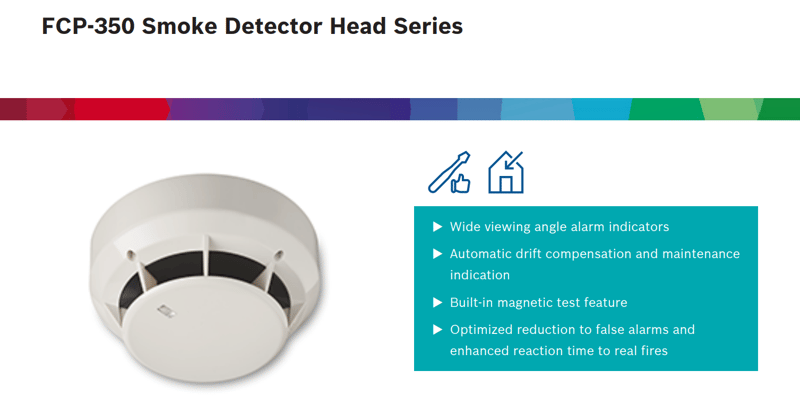

Bosch is proud to announce a new detector series which is compliant with UL 268, 7th Edition: FCP-350

The newly developed Bosch FCP-350 series multi-spectrum smoke categorization technology detects smoldering and flaming fires fueled by traditional materials and polyurethane while reducing nuisance alarms.

System overview

This device utilizes a green/red LED for indication of status. In a normal standby condition the LED flashes green every 3 seconds. When the detector senses that its sensitivity has drifted outside the UL listed

sensitivity window the LED will flash Red every 3 seconds. When the detector senses smoke and goes into alarm the status the LED will latch on Red.

Functions

This device utilizes an Infrared and Blue LED light source and silicon photodiode receiving element in the smoke chamber. In a normal standby condition, the receiving element receives no light from the pulsing LED light source. In the event of a fire, smoke enters the device smoke chamber and light is reflected from the smoke particles to the receiving element. The light received is converted into an electronic signal.

Fire Judgement signals are processed and compared to a reference level. When the signal exceeds the reference level, the alarm signal is triggered. The status LED latch on continuously during the alarm period.

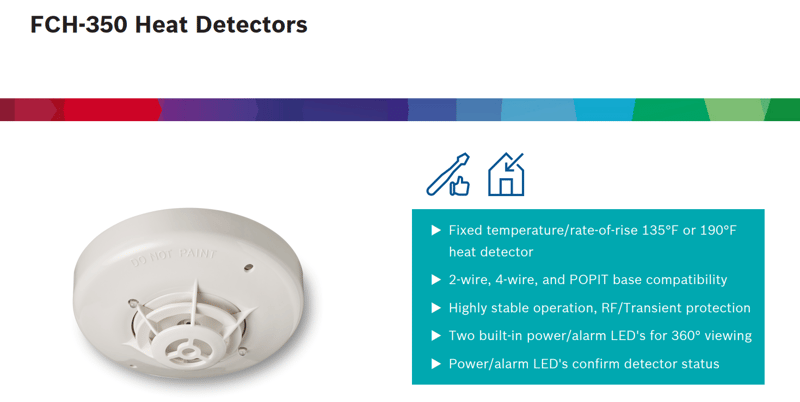

The FCH-350 series fixed temperature/rate-of-rise heat detectors are suited for installation where high heat output fires are expected or in areas where ambient conditions would not allow use of other detection methods. Heat detectors are intended for protection of property. Notice: Heat detectors are not life safety devices. Where life safety is a concern, smoke detectors must also be used. A UL listed fire alarm panel must electronically supervise the FCH-350-135/-190 heat detectors.

System overview

The FCH-350-135/-190 fixed temperature/rate-of-rise heat detectors are suited to detect in the presence of slow or fast rising temperatures due to burning combustibles. The construction of these models incorporate a thermistor heat element protected from damage by the built-in, durable plastic guard.

These electronic heat detectors incorporate two power/ alarm LED's for 360° indication of status. In standby condition the power LED's flash green. In an alarm condition the LED's latch on red. The FCH-350-135/-190 electronic heat detection circuitry performs the same function as a Mechanical Device, but with Electronic Precision. If the heat rise is less than 12°/minute the detector will not alarm until it reaches its alarm temperature (135° or 190° ± 7.5°F). If the heat rise is greater than 12°/minute the detector will alarm immediately giving an early warning signal and latching the Red alarm LED's on.

Functions

The FCH-350-135F can be installed in ambient temperatures that do not exceed 120°F. For areas where ambient temperatures exceed 120°F, but not 160°F, the FCH-350-190 fixed temperature/rate-of-rise heat detector rated at 190°F can be used. Electrical contacts shall be normally open, rated at 150mA @ 24VDC.

Heat detectors shall be installed in accordance with National Fire Protection Association Standard 72, the spacing assigned by Underwriters Laboratories and in accordance with the rules and regulations set forth by the local authorities having jurisdiction. Automatic heat detectors shall be Underwriters Laboratories

listed.

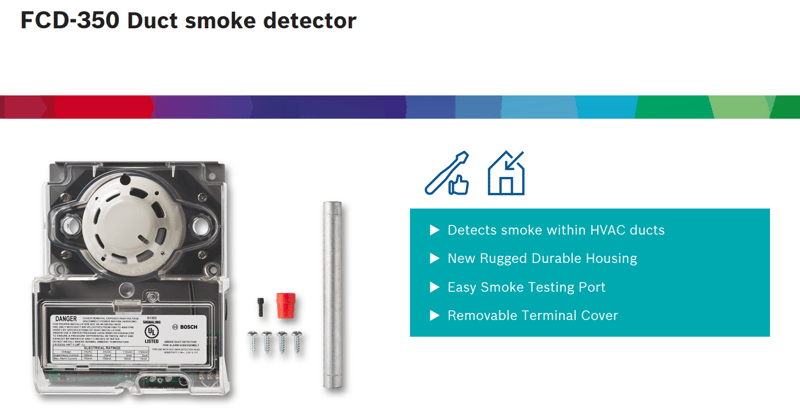

The FCD-350 duct smoke detector is designed and built to meet all local requirements, as well as the NFPA regulations regarding duct smoke detectors. This device has a local test button, and output terminals for remote status indicators and test switches. Air sampling is accomplished by two tubes which protrude into the duct. The 7.5 in. exhaust tube is supplied with the duct smoke detector unit. Once the duct width has been determined the air intake sampling tubes must be ordered. Sampling tubes are supplied in three standard lengths 2.5ft., 5 ft. and 10ft. and cut to size to fit the duct.

Functions

This device detects the presence of smoke in HVAC ducts and trigger an alarm to the connected system in order to reduce the recirculation of smoke in areas by the air handling systems, fans and blowers. Complete systems may be shut down in the event of smoke detection. This device operates on 120VAC, 240VAC, 24VAC, or 24VDC.

Installation/configuration notes

Wiring must conform to applicable local codes, ordinances and regulations covering these types of devices. Wire the detectors according to the engineering drawings for the particular job requirements. These detectors are not intended for open area protection, nor should they be used for open air protection. Refer to NFPA 90A and NFPA 72 for general and additional information on Duct Smoke Detectors concerning operation and installation. Terminals are suitable for up to #14 gauge wire.

Fxx Series Accessories

NOTE: The two wire bases and addressable bases are designed for use with Bosch control panels only. The four wire bases are compatible with any 12VDC or 24VDC control panel.

System design assistance

For help choosing the right smoke detector and designing your solution, please contact us at support@midches.com